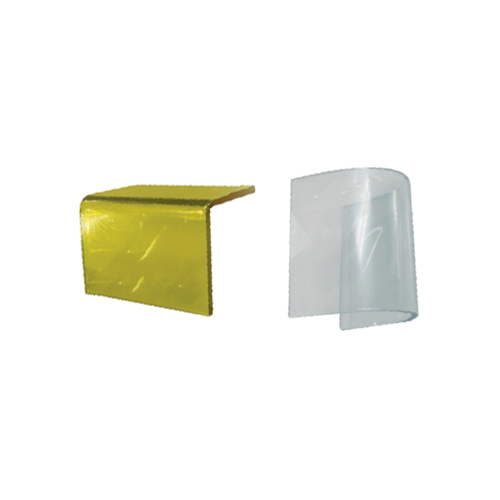

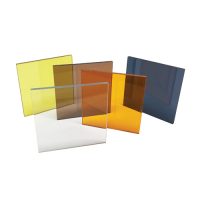

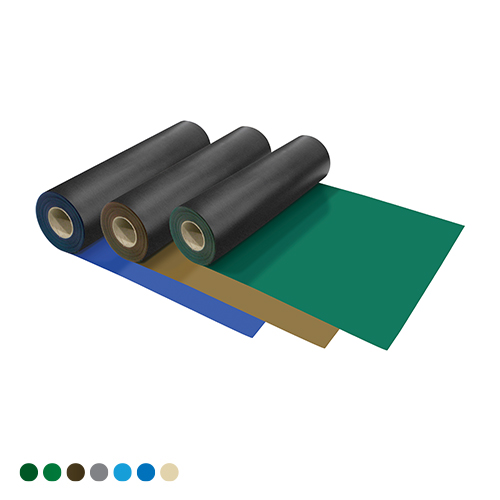

Polstar Static Dissipative Plate (PSDP) features a special ESD hard-coating on both surfaces, providing a semi- permanent surface resistance of <10e9 ohms, effectively eliminating static electricity. PSDP is ideal for rapidly dissipating static charges without causing harmful arcing on the surface of vulnerable components. PSDP meets electrical and optical requirements while offering superior abrasion resistance, a non-scratchable surface, and chemical resistance. PSDP is available in Polycarbonate (for high-temperature performance, fire resistance, and outstanding impact resistance), PMMA (offering high pencil hardness and excellent clarity), PVC (with excellent chemical resistance), and Aluminum Composite Panels, catering to a wide range of applications across various industries. The newly designed PSDP series is also available for specialized bending and bonding applications (please note that Polycarbonate is not suitable for bonding) without developing surface cracks and without altering surface resistance after the bending process.

Static Dissipative Plate

Description

Specifications & Product Information

| Properties | Testing Item | Unit | PC (Polycarbonate) |

PMMA (Acrylic) |

PVC (Polyvinyl Chloride) |

AL (Aluminum) |

Test Method |

| M03Y-000 | M01Y-000 | M02Y-000 | M04Y-000 | ||||

| Physical Properties |

Specific Gravity | g/cm2 | 1.2 | 1.19 | 1.4 | 1.38 | ASTM D-792 |

| Water Absorption | % | 0.1 | 0.3 | 0.01 | – | ASTM D-570 | |

| Pencil Hardness | – | HB | 3H~5H | 3H | 3H~5H | JIS K-5400 | |

| Piece Close Adhesion Strength | – | 100/100 | 100/100 | 100/100 | 100/100 | JIS K-5400 | |

| Mechanical Properties |

Tensile Strength | Mpa (kgf/cm2) | 58.8~68.6 600~700 |

560~670 | 650 | 8.5 | ASTM D-638 |

| Elongation | % | 90~140 | 2.0~7.0 | 20 | 27 | ASTM D- 638 | |

| Flexural Strength | kgf/cm2 | 920~980 | 840~1200 | 920 | 1344 | ASTM D-790 | |

| Flexural Modulus of Elasticity | kgf/cm2 | 2500 | 2.6 × 104 ~3.2 × 104 |

2.6 × 104 | 3746 | ASTM D-256 | |

| Compressive Strength | Jkgf/cm2 | – | – | 1142 | – | ASTM D-256 | |

| Izod Shock Strength | J/M (kgf cm/cm2) | 6 | 2 | 6 | – | ASTM D-256 | |

| Thermal Properties | Burning Resistance | – | Incombustibility V0~V2 |

Incombustibility HB |

Incombustibility V-0 |

Incombustibility V-0 |

UL-94 |

| Coefficient of Linear Thermal Expansion | X10-5in/in˚F | 3.8 | – | – | – | ASTM D-696 | |

| Heat Deflection Temp. | ˚F/˚C at 264psi | 270/132 | – | – | – | ASTM D-648 | |

| Vicat Softening Temp. | ˚F/˚C | 310/154 | – | – | – | ASTM D-3418 | |

| Max Operation Temp. | ˚F/˚C | 170/77 | – | – | – | – | |

| Thermal Conductivity | BTU-in/ft2-hr-˚F | 1.3 | – | – | – | ASTM D-177 | |

| X10-4cal/in/cm-sec-˚C | 4.5 | ||||||

| Electronical Properties | Surface Resistance | ohm | <10e9 | <10e9 | <10e9 | <10e9 | ASTM D-257 |

| Static Decay Time | Sec | Below 0.1 | Below 0.1 | Below 0.1 | Below 0.1 | MIL B-81705 B | |

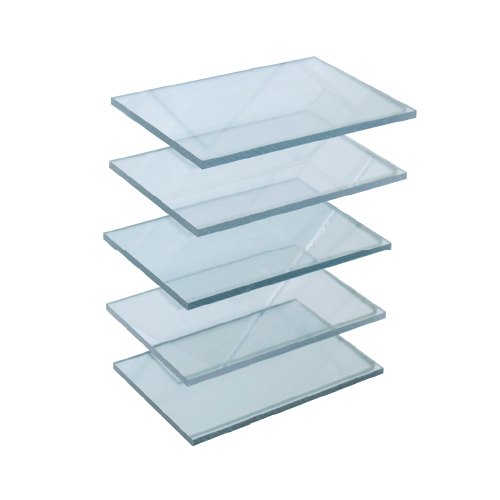

| Size | – | mm | 1,000 × 2,000 / 1,200 × 2,400 | ||||

| Thickness | – | mm | 2.0 / 3.0 / 4.0 / 5.0 / 6.0 / 8.0 / 10.0 | ||||

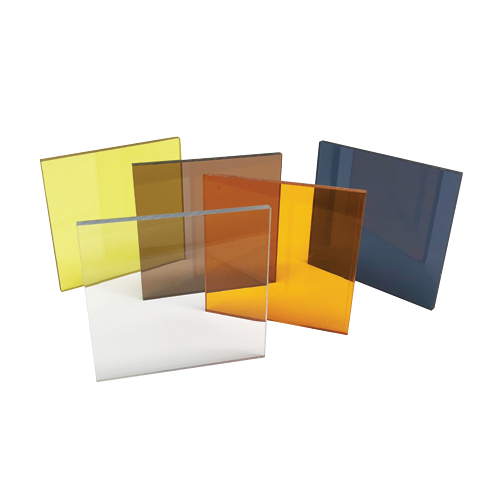

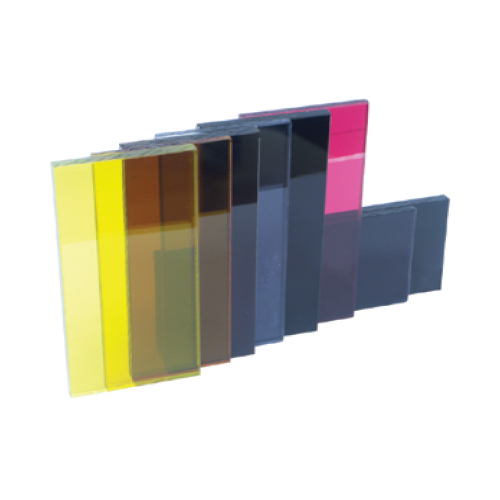

| Color | – | Clear transparent, Yellow, Orange, Blue, Brown, Smoke, Opaque in black or Ivory | |||||

| Remark | Other sizes, thicknesses and colors are also available upon request. | ||||||

Maintenance, Handling, Caution

- Recommendable storage conditions: less than 30℃, RH 40 ~ 60%.

- To avoid scratches on the surface, remove the protective film after PSDP has been machined.

- It is recommendable to have trials with test specimen to determine optimum settings before cutting or modification. Static dissipative coating must be removed from the surface to be glued.

- Isopropyl Alcohol (IPA) or alcohol-based cleaning liquid is recommendable for cleaning. PSDP is not required to be cleaned with antistatic plastic cleaners.

- Loss of static dissipative performance will occur if excess scratching is concentrated in a particular area.

- If PSDP is treated with a polishing machine, the performance of static dissipative coating cannot be guaranteed.

Applications

- Cleanroom manufacturing area

- Semiconductor and Electronics / TFT / LCD manufacturing area and equipment

- Pharmaceutical and Biomedical processing areas

- Food processing area

- Explosive manufacturing areas

- Aerospace / Automobile related area

- Equipment viewing windows and doors

- Equipment enclosures and covers

- IC chip conveyor systems

- Dot placement machine

- Stencil printing machine

- Wafer handling equipment

- Desiccator cabinets

- Transport boxes

- Perimeter glazing

- Transparent room partitions

- Glazing panels for mini-environment and pass-thru units

- Laminar flow applications

- Portable cleanroom panels

- Ceiling panels

- Mini-environment panels

- Microbiology filing table covers

- Sterile filling station panels

- Barrier system panels

- Insulator unit covers

- Machinery guards

- Separator panels

- Templates