Description

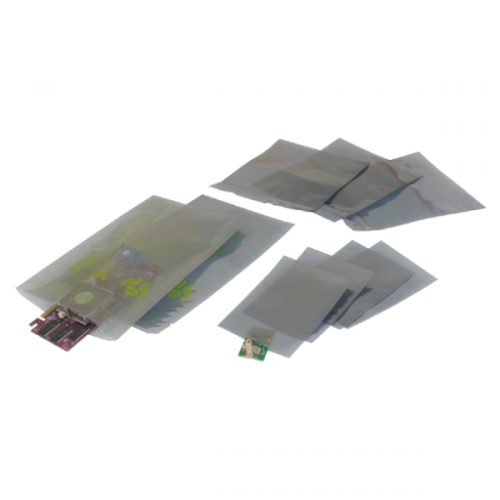

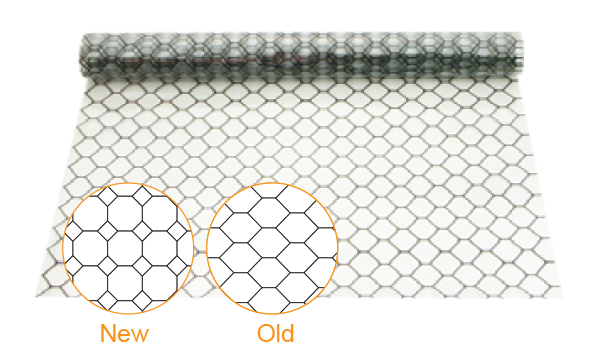

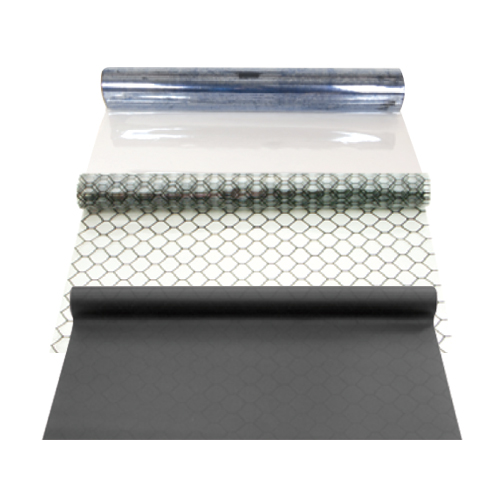

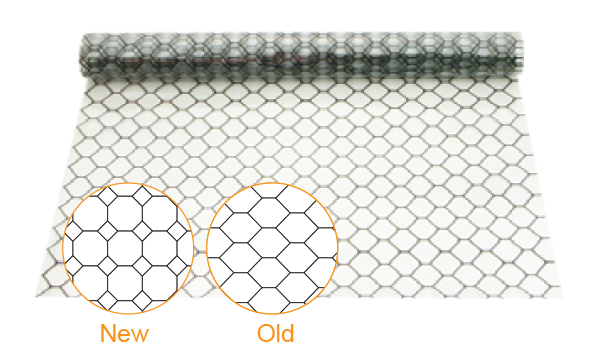

ESD Grid Curtain Film

Specially formulated conductive carbon grid printed on normal transparent PVC film. The surface resistance of the carbon printed side is 10e4~10e6 ohm.

| Model |

Item Code |

Size |

| P-PGF |

M05Y-004 |

0.3 mm(T)×1370 mm×30 m |

| M05Y-013 |

0.3 mm(T)×1370 mm×50 m |

| M05Y-009 |

0.5 mm(T)×1370 mm×20 m |

| M05Y-011 |

1 mm(T)×1000 mm×20 m |

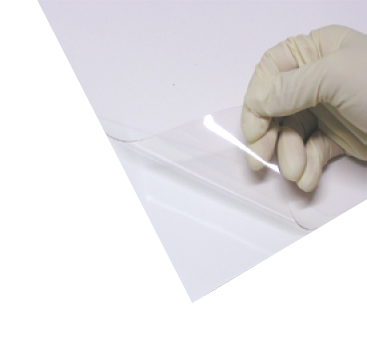

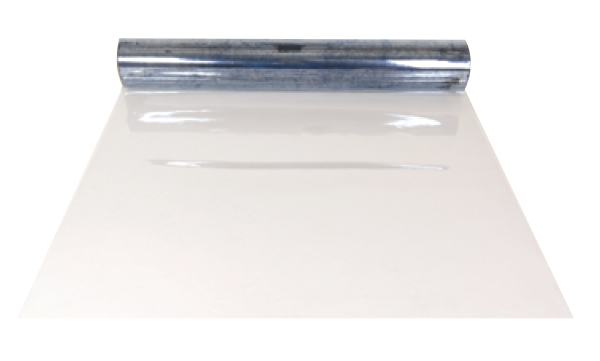

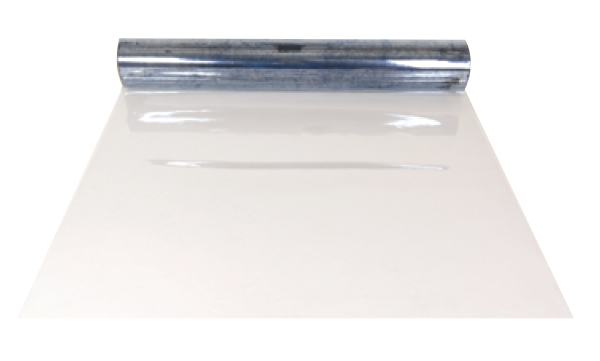

ESD Clear Curtain Film

This is a homogeneous antistatic transparent PVC film made of antistatic compounded PVC, not antistatic coated material. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.

This is a homogeneous antistatic transparent PVC film made of antistatic compounded PVC, not antistatic coated material. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.

| Model |

Item Code |

Size |

P-PCH

(Homogeneous Type) |

M06Y-002 |

0.3 mm(T)×1370 mm×30 m |

| M06Y-006 |

0.5 mm(T)×1370 mm×20 m |

| M06Y-010 |

1 mm(T)×1200 mm×20 m |

| M06Y-014 |

2 mm(T)×1200 mm×10 m |

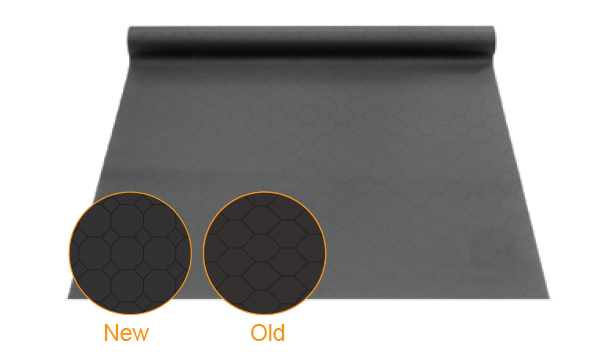

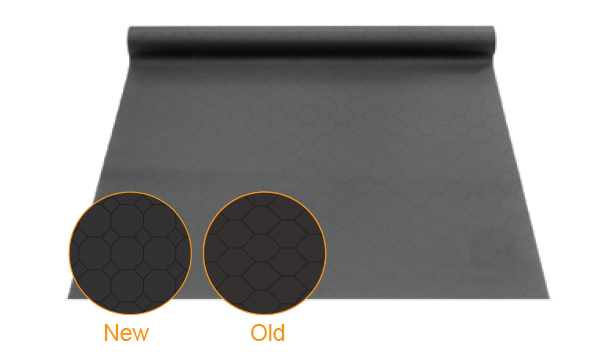

ESD Opaque Black Grid Curtain Film

This is not a homogeneous constitution, but a specially formulated conductive carbon grid printed on opaque black PVC film. The surface resistance of the carbon printed side is 10e4~10e6 ohm. This film is good for shielding screen effect with conductive surface.

| Model |

Item Code |

Size |

| P-PGB |

M09Y-001 |

0.3 mm(T)×1370 mm×30 m |

| M09Y-005 |

0.5 mm(T)×1370 mm×20 m |

ESD UV Clear Curtain Film

Homogeneous yellow tinted antistatic PVC film for the protection of harmful ultraviolet ray. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.

| Model |

Item Code |

Size |

P-PUH

(Homogeneous Type) |

M07Y-001 |

0.3 mm(T)×1370 mm×30 m |

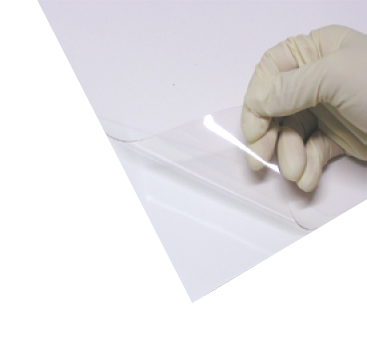

ESD Clear Adhesive Curtain Film

This is a homogeneous antistatic transparent PVC film with adhesive one side. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm. This film can be applied to any insulated walls, windows, partitions and other insulative materials.

| Model |

Item Code |

Size |

P-PAH

(Homogeneous Type) |

M11Y-001 |

0.25 mm(T)×1200 mm×10 m |

ESD Opaque Black Curtain Film

This is a homogeneous antistatic opaque black PVC film made of antistatic compounded PVC, not antistatic coated material. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.

| Model |

Item Code |

Size |

P-PBH

(Homogeneous Type) |

M10Y-001 |

0.3 mm(T)×1370 mm×30 m |

ESD Opaque Black Grid Curtain Film , Both sides

This is not a homogeneous constitution, but a specially formulated conductive carbon grid printed on opaque black PVC film on both sides. The surface resistance of the Both sides are 10e4 ~10e6 ohm.

| Model |

Item Code |

Size |

| P-PGG |

M09Y-002 |

0.3 mm(T)×1370 mm×30 m |

| M09Y-003 |

0.5 mm(T)×1370 mm×20 m |

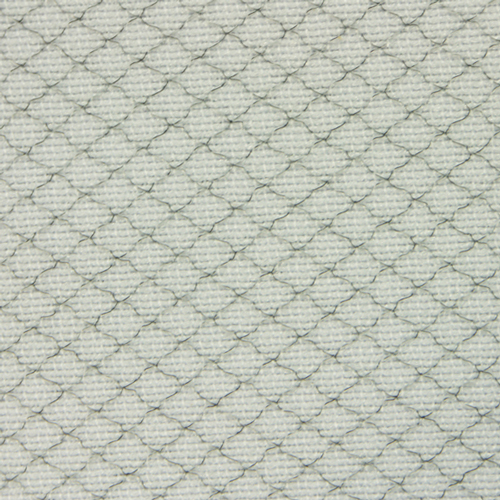

Specifications & Product Information

| Electrical Properties |

| DESCRIPTIONS |

ITEM |

P-PCH

P-PBH

P-PAH

P-PSF

P-PFF |

P-PUH |

P-PGF |

P-PGB |

P-PGG |

Unit |

Test Method |

Surface

Resistance |

Front |

108~1010 |

108~1010 |

105~108 |

105~108 |

105~108 |

ohm |

ASTM D-257 |

| Back |

108~1010 |

108~1010 |

> 1011 |

> 1011 |

105~108 |

| Volume Resistance |

107~109 |

107~109 |

> 1011 |

> 1011 |

> 1011 |

ohm |

ASTM D-257 |

Friction

Electrocharge |

Front |

< 100 |

< 100 |

< 1000 |

< 1000 |

< 1000 |

voltage |

Electro Static Field Meter

(10times rubbing by cotton,

23℃ × 24%RH) |

| Back |

< 100 |

< 100 |

– |

– |

< 1000 |

| Decay time |

5000V – 500V |

< 0.5 |

sec |

MIL-B-81750C |

| Physical Porperties |

Tensile

Strength |

MD |

1.90 |

1.90 |

1.90 |

1.90 |

1.90 |

kg/mm2 |

ASTM D-882 |

| TD |

1.90 |

1.90 |

1.90 |

1.90 |

1.90 |

100%

Modulus |

MD |

1.10 |

1.10 |

1.10 |

1.10 |

1.10 |

| TD |

1.80 |

1.80 |

1.80 |

1.80 |

1.80 |

| Elongation |

MD |

170 |

170 |

170 |

170 |

170 |

% |

| TD |

210 |

210 |

210 |

210 |

210 |

UV

Transmissivity |

UV-H |

– |

99.50 |

– |

– |

– |

% |

KS K 0850-1999 |

| UV-B |

– |

95.40 |

– |

– |

– |

| UV-A |

– |

9.5 |

– |

– |

– |

| Heat Shrinkage |

< 5 |

% |

Internal Method

(60℃ ×30min in H2O) |

| Resistance to Chemicals |

| Hydrochloric Acid (10%) |

○ |

|

JIS K-7114 5 cm×5 cm

Size of Specimen: Dipped for 168hrs |

| Sulfuric Acid (10%) |

○ |

| Acetic Acid (5%) |

○ |

| Sodium Hydroxide (10%) |

○ |

| Aqueous Ammonia (10%) |

○ |

| Ethyl Alcohol (50%) |

△ |

| Acetone (95%) |

△ |

| Benzene (95%) |

X |

| Formalin (95%) |

○ |

| Available Sizes |

| Thickness (mm) |

0.1, 0.2, 0.25, 0.3, 0.5, 1.0, 2.0, 3.0 |

| Width (cm) |

20, 30, 90, 100, 120, 137 |

| Length (m) |

10, 20, 30, 50 |

This is a homogeneous antistatic transparent PVC film made of antistatic compounded PVC, not antistatic coated material. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.

This is a homogeneous antistatic transparent PVC film made of antistatic compounded PVC, not antistatic coated material. ESD properties remain permanent. The surface resistance is 10e8~10e10 ohm and the volume resistance is 10e7~10e9 ohm.