Copper Tape

| Item Code | M07M-004 |

| Size | 0.038 mm (T) × 10 mm (W) |

| Packing | 30 m/roll |

Conductive Adhesive

| Item Code | M10M-005 |

| Type | Carbon Fiber Type |

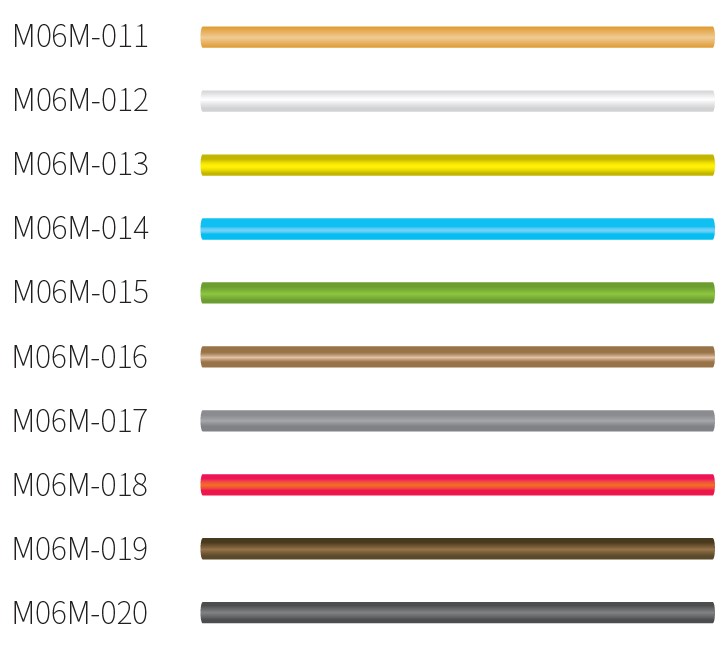

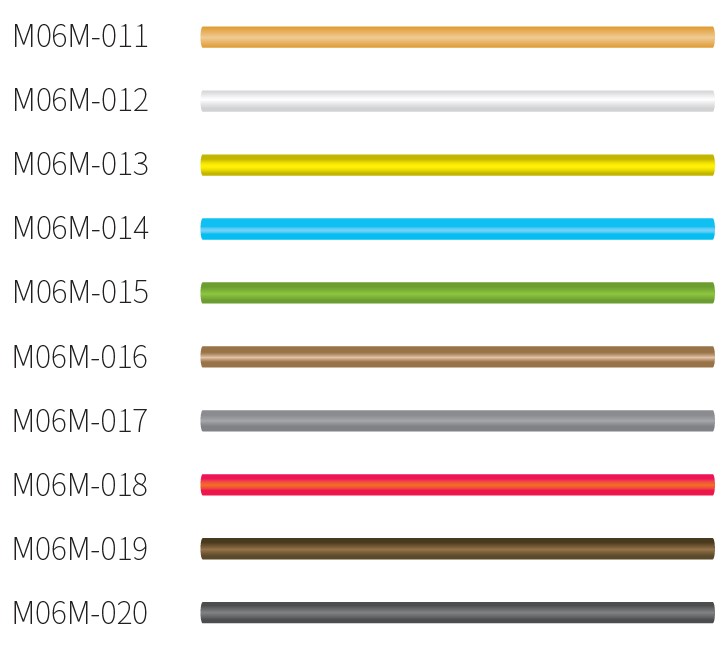

Welding Rod

| Item Code | M07M-004 |

| Size | 0.038 mm (T) × 10 mm (W) |

| Packing | 30 m/roll |

| Item Code | M10M-005 |

| Type | Carbon Fiber Type |

1. Preparation of Subfloor

1) Flatness

• Maximum variation of the subfloor allowable is 3.0mm in 3 meter square.

2) Humidity of concrete subfloor

• Under 5.0LBS per 1,000sqft in 24 hours by Calcium Chloride Moisture Test in accordance with ASTM E 1907/ASTM F 1869.

• Under 2.5% measured with CM Hygrometer (without floor heating)

3) PH Level

•Under 10

4) Smoothness and Surface

• Subfloor must be clean, dry and free from dust and dirt.

• Cracks and irregular surface must be patched and leveled, using a good grade of the floor finishing materials, like smoothing compound, etc.

5) Prior to installation, the flooring tiles should be acclimated for at least 48 hours.

6) Recommendable temperature will be at 20℃. (At least from 18℃ to 30℃) and constant temperature should be maintained during and after the installation for at least 48 hours.

2. Conductive Adhesive

Suitable adhesive should be consulted and selected by authorized personnel, who manage the job site conditions, from the following selections:

• Carbon Fiber Type : Water based fiber mixed Conductive acryl adhesive

• Carbon Powder Type : Water based carbon mixed Conductive acryl adhesive

• 2 Parts Epoxy : 2 component environment friendly conductive epoxy adhesive

• PU Epoxy : Solvent based Conductive Urethane Rubber Adhesive

The recommended quantity of adhesive is 0.25kg / sqmt.

3. Copper Tape

• Install the Copper Tape according to the interval standard of floor electric resistance requirements (ConductiveTile : 3m, Static Dissipative: 6~8m in cross section)

• Crossing points of Copper Tape lines should be punched in 3 mm diameter to secure the connection.

• Final grounding connection to the grounding points must be performed by authorized electrician or engineer.

4. Welding

• Seamless floor covering can be applied to prevent moisture troubles and to reduce dust and particles rising from the floors.

• Make the groove around 70~80% depth comparing to the original thickness of the tiles using electric grooving or hand grooving tools

• Trim off the excess parts of welding rod with the crescent -shape knife after the welding.