Features

- Excellent physical properties

- Tailored to various customers’ needs

- Wide ESD range (10e2 ~ 10e8 Ω/sq)

Features

| Item Code | M01V-000 | M04V-000 | M05V-000 | |||

| Base Resin | PP | PS | PE | |||

| ① | ② | ③ | ④ | |||

| Melt Index (g/10min) | 2 ~ 8 | 2 ~ 8 | 2 ~ 8 | 0.5 ~ 1.0 | 3 ~ 8 | 2 ~ 8 |

| Specific Gravity (23℃ g/cc) | 1.08 ~ 1.12 | 1.08 ~ 1.12 | 1.08 ~ 1.12 | 1.10 ~ 1.20 | 1.05 ~ 1.15 | 1.08 ~ 1.12 |

| Conductivity (23℃ Ω/sq) | 10e4 ~ 10e5 | 10e5 ~ 10e6 | 10e6 ~ 10e7 | 10e2 ~ 10e4 | 10e5 ~ 10e6 | 10e4 ~ 10e5 |

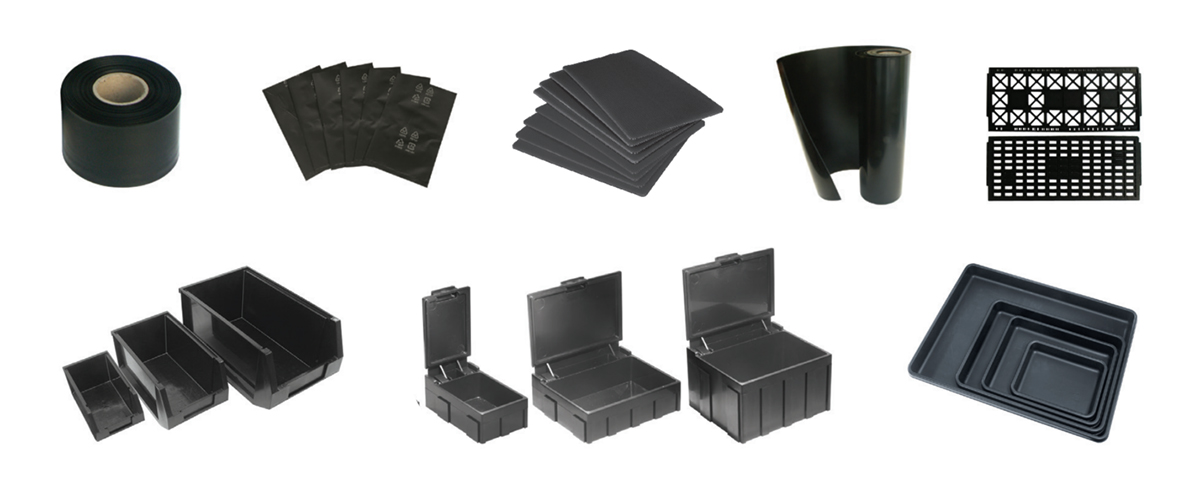

| Applications |

|

|

|

|||