Tyvek MBB is ideal for moisture sensitive devices or components, and especially suitable for sharp-shape components thanks to its excellent puncture resistance.

| Item Code | M01P-000 |

| Thickness | 307 ㎛, 247 ㎛ |

| MVTR* | < 0.02 g/100 sqinch/24h |

Tyvek MBB is ideal for moisture sensitive devices or components, and especially suitable for sharp-shape components thanks to its excellent puncture resistance.

| Item Code | M01P-000 |

| Thickness | 307 ㎛, 247 ㎛ |

| MVTR* | < 0.02 g/100 sqinch/24h |

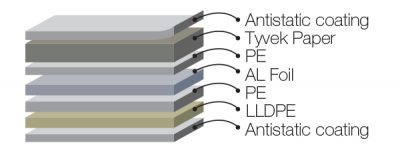

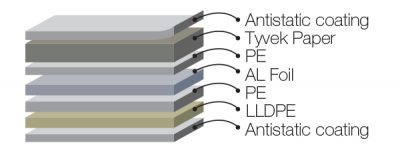

It is essential to keep Surface-Mount Devices (SMDs) dry from manufacturing point to the time of reflow soldering. Moisture Barrier Bag, also known as Vapor Barrier Bag, is made by multiple layers of plastic and a thin aluminium layer or aluminized layer that controls moisture vapor leakage. Basically, there are 3 kinds of Moisture Barrier Bags(MBBs), Tyvek MBB, AMBB and ANMBB, in the market. The key factor of moisture barrier function of the bag is a metal layer or a metalized layer, like thickness of the foil layer, metalized layer, etc., but the thickness or the material of other layers also affects the quality of MBB as well.

Mil – 0.001 inch, ex) 3 mils = 0.003 x 25.4 mm = 0.0762 mm = 76.2 microns

Micron – 1/1,000,000 m (1/1,000 mm = 0.001 mm), ex.) 100 microns = 100/25.4 = 3.93 mils

MM – 0.15 mm = 150 microns

The Moisture Vapor Transmission Rate (MVTR) is the rate that water vapor passes through a specific area of barrier material. MVTR is measured in grams of water vapor per 100 square inches of barrier per 24 hours (g/100 in.2/24 h). EIA 583 Packaging Material Standards for Moisture-Sensitive Items defindes a Class 1 barrier as having an MVTR of <0.02 g/100 in.2/24 h. A Class 2 barrier is set at <0.08 g/100 in.2/24 h.