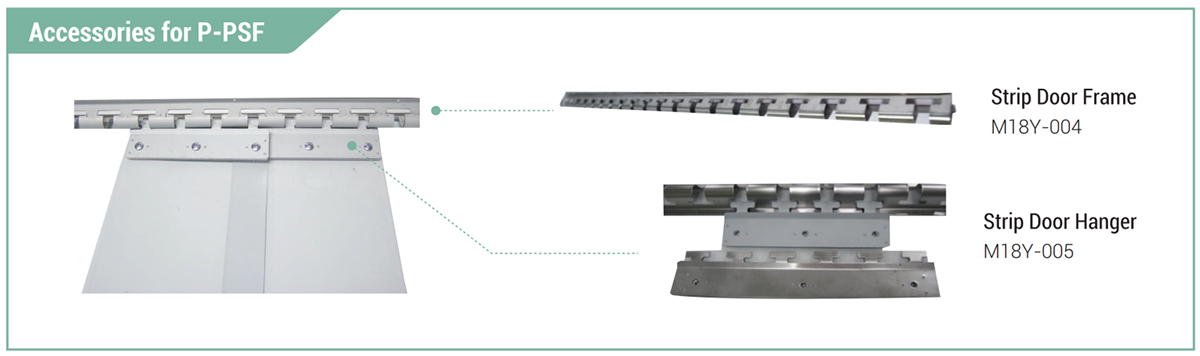

Description

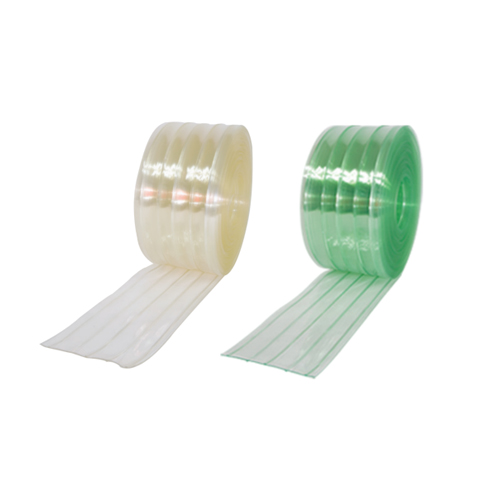

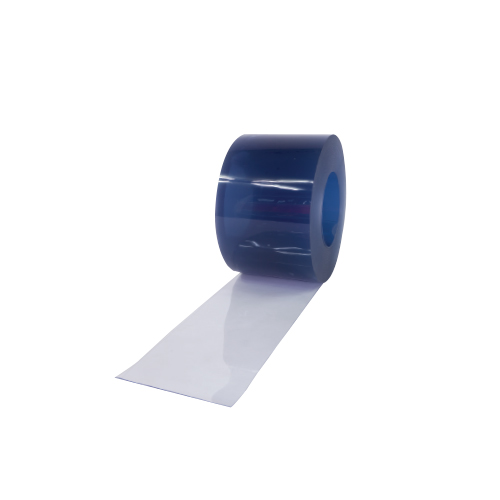

ESD Strip Door Curtain Film

Polstar Strip Door Curtain Film is recommendable to be installed at the gates or the entrances of factories that are frequently opened and closed. It saves energy by keeping the temperature of the factories. It also prevents wind, insects and any foreign materials from coming inside of the factories. General purpose of strip door curtain film, cold resistant strip door curtain film, anti-insect strip door curtain film and anti-static strip door curtain film are available.

| Item Code | M16Y-000 |

| Model | P-PSF |

| Surface Resistance | 10e8~10e10 ohm |

| Color | Bluish Tansparent / Greenish Transparent |

| Available Sizes | 2 mm(T) × 200 mm × 30 m |

| 2 mm(T) × 300 mm × 30 m | |

| 3 mm(T) × 300 mm × 30 m |

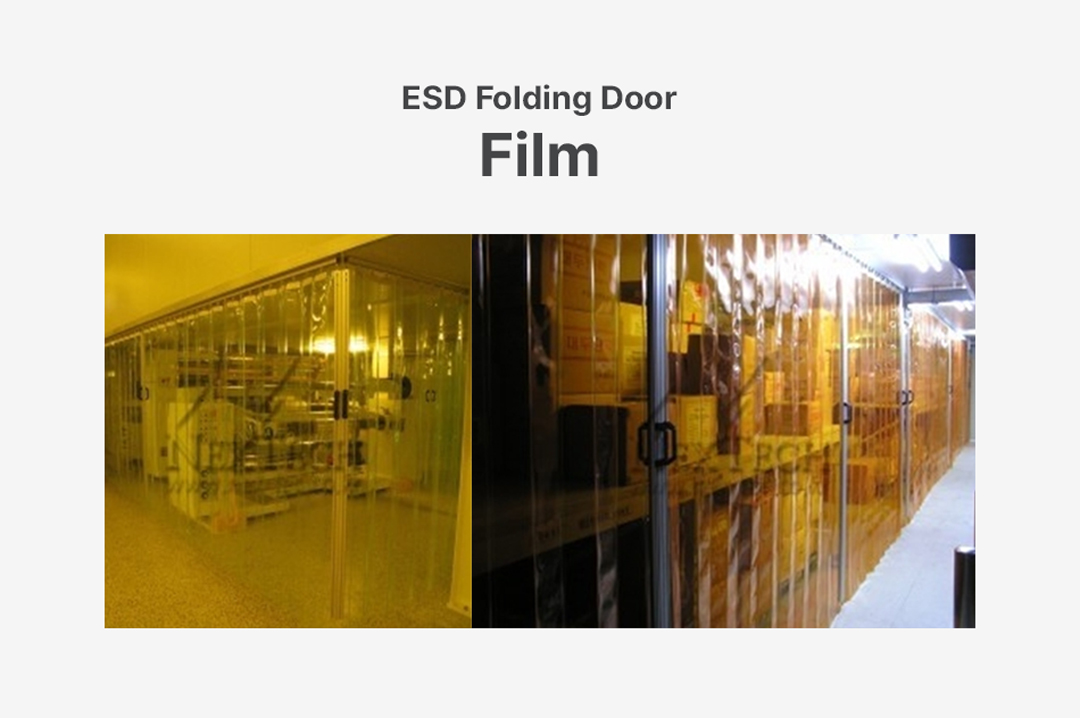

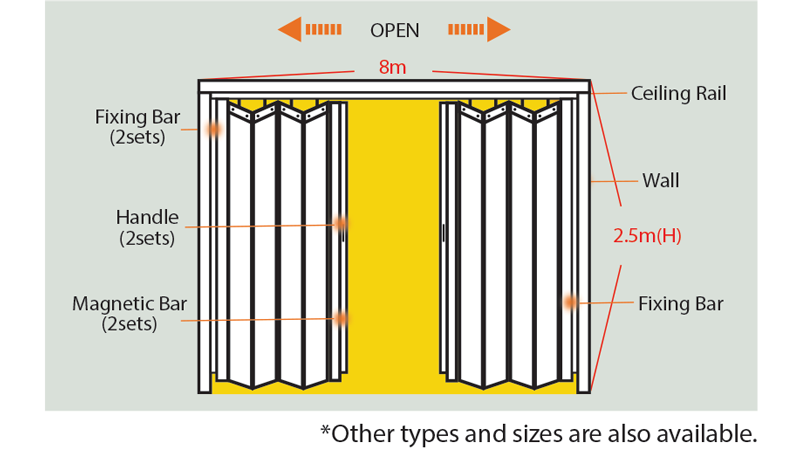

ESD Folding Door Film

Homogeneous antistatic foldable film is suitable to make clean booths, soft partitions, walls, doors, etc. The standard size is 1.35 mm(T)×1000 mm(W)×12 m(L) and there are 8 folding lines in 1000mm width all the way to the length diretion. Two colors, greenish clear and yellowish clear, are available.

| Item Code | M21Y-000 |

| Model | P-PFF |

| Surface Resistance | 10e8~10e10 ohm |

| Color | Yellowish, Greenish Transparent |

| Available Sizes | 1.35 mm(T)×1000 mm(W)×12 m(L) |

Specifications & Product Information

| Electrical Properties | ||||||||

| DESCRIPTIONS | ITEM | P-PCH P-PBH P-PAH P-PSF P-PFF |

P-PUH | P-PGF | P-PGB | P-PGG | Unit | Test Method |

| Surface Resistance |

Front | 108~1010 | 108~1010 | 105~108 | 105~108 | 105~108 | ohm | ASTM D-257 |

| Back | 108~1010 | 108~1010 | > 1011 | > 1011 | 105~108 | |||

| Volume Resistance | 107~109 | 107~109 | > 1011 | > 1011 | > 1011 | ohm | ASTM D-257 | |

| Friction Electrocharge |

Front | < 100 | < 100 | < 1000 | < 1000 | < 1000 | voltage | Electro Static Field Meter (10times rubbing by cotton, 23℃ × 24%RH) |

| Back | < 100 | < 100 | – | – | < 1000 | |||

| Decay time | 5000V – 500V | < 0.5 | sec | MIL-B-81750C | ||||

| Physical Porperties | ||||||||

| Tensile Strength |

MD | 1.90 | 1.90 | 1.90 | 1.90 | 1.90 | kg/mm2 | ASTM D-882 |

| TD | 1.90 | 1.90 | 1.90 | 1.90 | 1.90 | |||

| 100% Modulus |

MD | 1.10 | 1.10 | 1.10 | 1.10 | 1.10 | ||

| TD | 1.80 | 1.80 | 1.80 | 1.80 | 1.80 | |||

| Elongation | MD | 170 | 170 | 170 | 170 | 170 | % | |

| TD | 210 | 210 | 210 | 210 | 210 | |||

| UV Transmissivity |

UV-H | – | 99.50 | – | – | – | % | KS K 0850-1999 |

| UV-B | – | 95.40 | – | – | – | |||

| UV-A | – | 9.5 | – | – | – | |||

| Heat Shrinkage | < 5 | % | Internal Method (60℃ ×30min in H2O) |

|||||

| Resistance to Chemicals | ||||||||

| Hydrochloric Acid (10%) | ○ | JIS K-7114 5 cm×5 cm Size of Specimen: Dipped for 168hrs |

||||||

| Sulfuric Acid (10%) | ○ | |||||||

| Acetic Acid (5%) | ○ | |||||||

| Sodium Hydroxide (10%) | ○ | |||||||

| Aqueous Ammonia (10%) | ○ | |||||||

| Ethyl Alcohol (50%) | △ | |||||||

| Acetone (95%) | △ | |||||||

| Benzene (95%) | X | |||||||

| Formalin (95%) | ○ | |||||||

| Available Sizes | ||||||||

| Thickness (mm) | 0.1, 0.2, 0.25, 0.3, 0.5, 1.0, 2.0, 3.0 | |||||||

| Width (cm) | 20, 30, 90, 100, 120, 137 | |||||||

| Length (m) | 10, 20, 30, 50 | |||||||